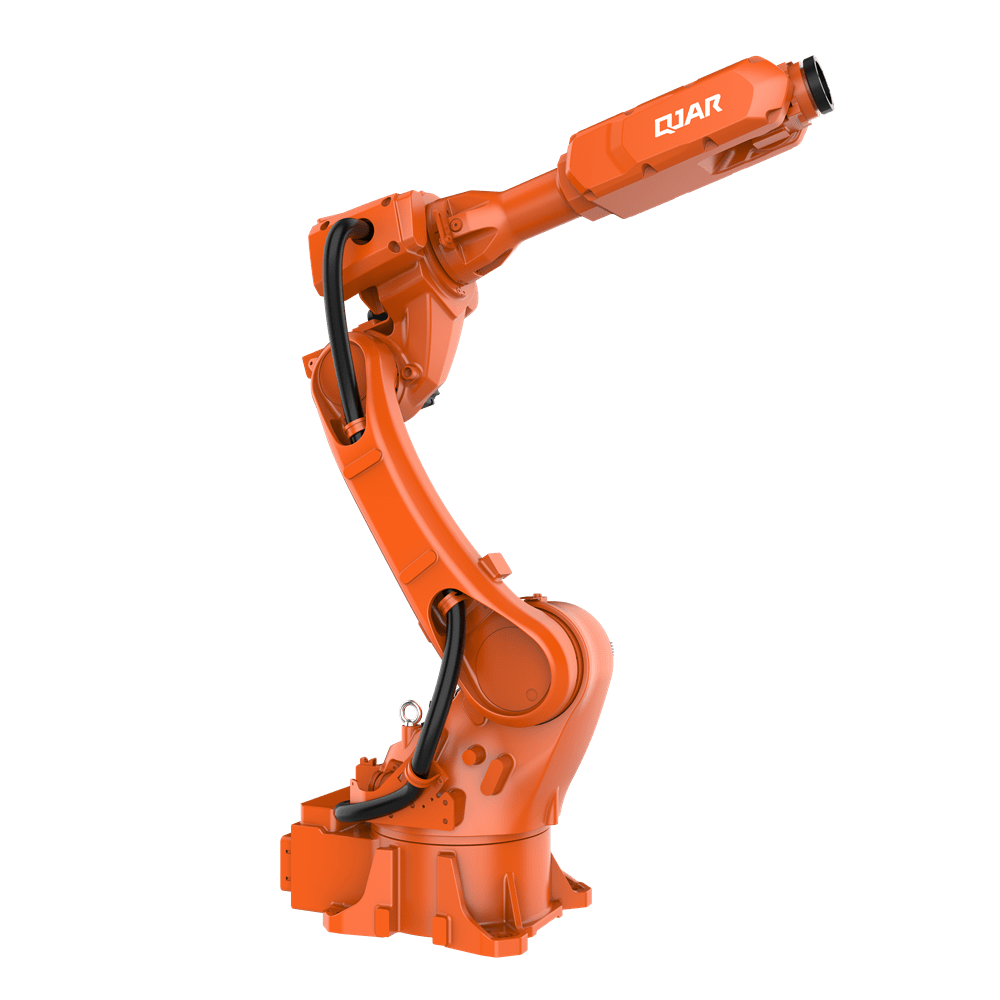

QJR6-2000H

• Improved reducer with large reduction ratio design, controls better;

• 4th axis hollow structure used double angle contact bearings instead of traditional. spread of stiffness of connections;

• 4, 6 axes with special particle adjustment structure, higher transmission precision;

• Converted to a U-shaped structure to increase wrist displacement;

With the above features, the motion stability of the extended welding robot is greatly optimized;

• The wrist is shortened to increase flexibility;

• Special wrist noise-reducing structure, lower operating sound;

• New appearance with new spray painting process, excellent sensory effect.

Product Meta

QJR6-2000H.

Categories: 6 Axis Robot Arm, Assembling Robot Arm, Sorting Robot Arm, Welding Robot Arm

Product Description

QJR6-2000H Technical Details

| Model | QJR6-2000H | |

| Axis Number | 6 | |

| Payload | 6kg | |

| Repeat Positioning | ±0.08mm | |

| Max Armspan | 2014mm | |

| Motion Range | J1 | ±175º |

| J2 | ﹢159º,﹣95º | |

| J3 | ﹢95º,﹣125º | |

| J4 | ±183º | |

| J5 | +129°,-126° | |

| J6 | ±360º | |

| Max Speed | J1 | 189 °/s |

| J2 | 189 °/s | |

| J3 | 189 °/s | |

| J4 | 360 °/s | |

| J5 | 320 °/s | |

| J6 | 974 °/s | |

| Allowable Torque | J4 | 8.81N.m |

| J5 | 8.81N.m | |

| J6 | 3.14N.m | |

| Inertia Moment | J4 | 0.2kg.m² |

| J5 | 0.2kg.m² | |

| J6 | 0.03kg.m² | |

| Robot Body Weight | 230kg | |

| Power Capacity | 3.4kVA | |

| Cabinet Size | 580*600*960mm | |

| Cabinet Weight | 130kg | |

| Source | Three-phase four-wire | |

| Installing Form | Ground Mounted/wall-mounted | |

| Application | Welding With welding package(welding machine aotai AMIG 350R or Megmeet Ehave CM350AR, wire feeder, anti-collision welding gun | |